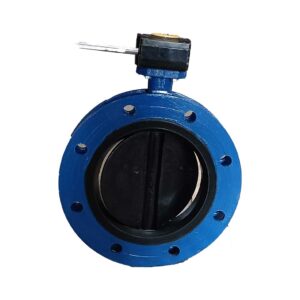

DPCV (Dual Plate Type Check Valves)

A Dual Plate Type Check Valve (DPCV) is a compact and efficient mechanical valve designed to control the flow of fluids in a pipeline. It consists of two hinged plates that swing open to allow the fluid to flow in one direction and close to prevent backflow. DPCVs are widely used in various industries to ensure one-way flow, prevent reverse flow, and reduce pressure loss. Their dual-plate design offers improved sealing and reliability compared to traditional swing check valves, making them a popular choice for fluid control applications.

Additional information

| Material Construction | Cast Iron, Cast Steel, Ductile Iron |

|---|---|

| Mfg Std/Testing Std | API 594 / 598 |

| Class | Up to PN-40 |

| Size (mm) | 25-2600 |

| Operation | Automatic Double Flanged Type |

A Dual Plate Type Check Valve, often abbreviated as DPCV, is a specialized mechanical device used in various fluid handling systems to control the flow of liquids or gases in a single direction. This valve is designed with two semi-circular plates or discs that swing on hinges or pivot points within the valve body. The primary purpose of a DPCV is to prevent backflow or reverse flow, ensuring that the fluid can only flow in one direction, which is typically from the inlet to the outlet.

The operation of a Dual Plate Type Check Valve is relatively straightforward:

When there is flow in the desired direction (from the inlet to the outlet), the fluid pushes the plates open against the hinge, allowing the fluid to pass through the valve.

If there is a reverse flow or backflow, the fluid pressure exerts force on the plates in the opposite direction, causing them to swing shut, effectively sealing the valve. This prevents the reverse flow of fluid.

Dual Plate Type Check Valves are essential components in various industries where controlling the direction of fluid flow is critical. Their simple yet effective design, along with their reliability and compactness, makes them a popular choice for a wide range of applications.