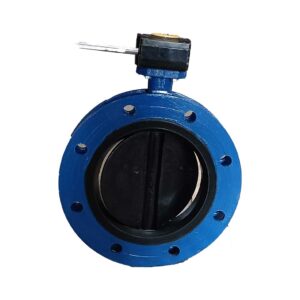

Resilient Seat Swing Check Valves

Resilient seat swing check valves are a type of mechanical valve used in piping systems to prevent the backflow of fluids. They are equipped with a flexible, elastomeric seat that provides a tight seal when the valve is closed, effectively preventing the reverse flow of liquids or gases. These valves are commonly employed in applications where reliable and low-maintenance backflow prevention is required, such as in water and wastewater systems, as well as in various industrial processes. The resilient seat design ensures a dependable seal while reducing the risk of leakage, making them a cost-effective solution for many fluid control applications.

Additional information

| Material Construction | Ductile Iron |

|---|---|

| Mfg Std/Testing Std | BS 5153 |

| Class | Up to PN-16 |

| Size (mm) | 50-400 |

| Operation | Automatic with Single Door |

Resilient seat swing check valves are essential components in fluid systems that play a critical role in preventing the reverse flow of fluids, such as liquids or gases. These valves are designed with a specific focus on durability, reliability, and efficient performance, making them a crucial element in a wide range of industries, from water treatment and wastewater management to oil and gas, petrochemical, and manufacturing processes.

A resilient seat swing check valve, also known simply as a swing check valve, features a hinged disc or flap that swings freely within the valve body. This disc moves in response to the flow of fluid through the pipeline, allowing fluid to flow in one direction while preventing it from flowing backward. The key characteristic that sets resilient seat swing check valves apart is their incorporation of a resilient or elastomeric seating material. This resilient seating material forms a tight seal around the disc, reducing the risk of leakage and ensuring efficient valve operation.